There is a growing number of energy simulation tools to support the increasing demand for energy efficient buildings. As an energy analyst, the challenge is knowing which is the most appropriate for a given application.

Validation of software platforms, in particular those suitable for simulating building related energy requirements are mostly undertaken by leading US institutions. This is largely due to a strong tradition of developing energy simulation tools combined with generous research funding and access to an entire international pool of talent to produce high fidelity tools such as EnergyPlus, in DeST and DOE-2.1E.

Of course, this is not to diminish the growing role of the Chinese scientific community in software validation efforts, as well as our own UK heritage such as the internationally recognised ESP-r building simulation program developed by Professor Joe Clarke.

A tale of two models

It was therefore an interesting challenge, when on the suggestion of Dr Sara Walker (Director of CESI, Newcastle University), myself and Dr Richard Johnson (University of Sheffield) started a collaboration to look at the comparative merits of two energy tools.

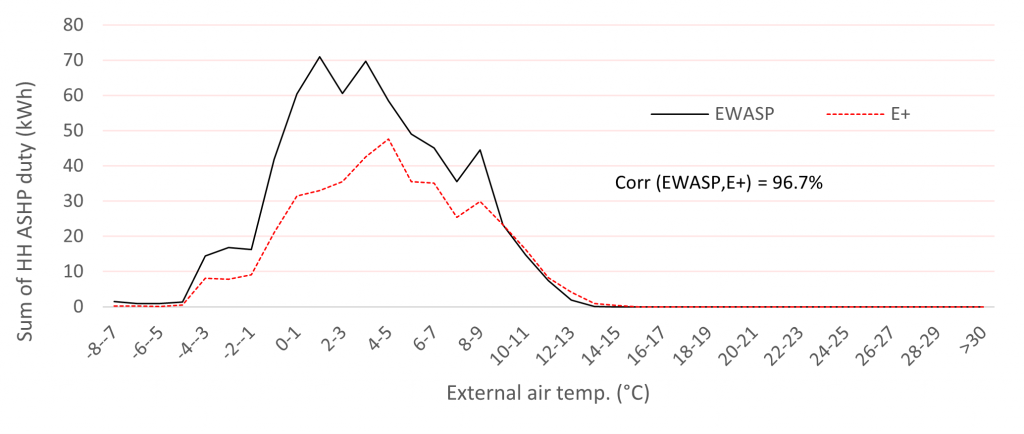

The first model for consideration is the EWASP; principally refined by R. Johnson, it produces high resolution air source heat pump loads. The second being EnergyPlus (E+) which remains one of the most sophisticated and complex first principle based physical tools for the simulation of building energy and its multiple sub-categories of loads.

Agility over luxury?

The key selling point of EWASP is its nimbleness. While E+ remains the Rolls-Royce of building simulation platforms, it is very complex and cumbersome, leaving the average energy analyst very prone to parameterisation mistakes.

By the same token a model in E+ can be time-consuming to develop. What we learned from this collaboration was that for the same medium size domestic property, E+ required 253 parameter inputs to describe the property and its thermo-physical characteristics, while the same property could be represented in EWASP using around 20 parameters.

This represents a 13-fold simplification! The E+ process is manual and can be error-prone due to it’s scale, especially if you are not used to using it. This 13-fold simplification reduces the development of a domestic model from around 40 hours of the analyst’s time to just 20 minutes.

Speed isn’t everything

The prediction accuracy of these tools requires more investigation. Quite understandably, with 253 parameter inputs, a huge space exists that needs to be explored to identify sources of error and divergence. Despite this – we found that when plotted against the main determinants of energy consumption (i.e. external air temperature), both models produced similar profiles of ASHP duties across the full annual cycle and against advancing air temperatures (Fig. 1).

The table below outlines some of the comparative findings of our initial work. As we progress, we might seek to invite some of our US colleagues from Berkeley Laboratory to collaborate with us for further insights.

Table 1: Description of parameter input values and computational resources for EWASP and E+ models

| Parameterisation | ||

| EWASP | EnergyPlus (E+) | |

| Weather Data | CIBSE Current TRY (NWL) | Same |

| Building Fabric | As outlined in Table 1 | Same |

| Indoor conditions | Time-dependent zone target temperature with setback value | Same |

| HVAC description | First-principle equations outlined in method | First-principle equations outlined in [1] |

| Occupant behaviour | Deterministic time-dependent profiles | Deterministic time-dependent fractional schedules |

| Computational | ||

| EWASP | EnergyPlus (E+) | |

| Engine | Intel(R) Core ™ i5-8350U CPU @ 1.7 GHz 1.9 GHz (RAM:16 GB) | Same |

| Operating system | Windows 10 (x64-based processor) | Same |

| Parameter inputs (no.) | 20 | 253 [1] |

| Parameterisation time | 15 min | 40 hours [2] |

| Simulation time (Sec.) | 5800 | 405 [3] |

| Simulation output (datapoints) | 6,307,200 [4] | 3,661,680 [5] |

[1] Based on 182 input requirements to define HVAC, lighting, opaque and solid construction components and human activities, with another 71 input parameters required for advanced analysts (e.g. the choice of algorithm for surface convection calculations).

[2] Using DesignBuilder as interface to create accurate building geometry, project specific templates to define fabric thermo-physical properties and zone activities, and detailed HVAC representation and assignment.

[3] Generation of Input Data Files (IDFs) to export to E+ engine, reloading back of the simulation results and generation of data for building blocks.

[4] EWASP simulates across the annual cycle at 5s interval, hence 6.3m datapoints at 5s timesteps.

[5] Based on half-hourly energy and environmental data for 11 zones.

Mohammad Royapoor of Newcastle University is a chartered engineer focusing on the design and optimisation of heating, ventilation and air conditioning (HVAC) services and contributes to the Active Building Centre Research Programme .